Advice

Are you dealing with rubber moulded parts, silicon moulded parts or rubber bonded parts? We support you with competent consultation in the production of prototypes, with the conception of the moulds or the development of moulded parts. The first sample will be accomplished according to the VDA or PPAP process. Of course also the entry in the IMDS database will follow.

Competence through experience is not an empty slogan: for decades we have been successfully active in our market segment. Functionality and enduring quality of our rubber bonded and rubber moulded parts paired up with a healthy cost benefit ratio distinguish us as a renowned company.

You too can profit from this. We are at your side if you would like to develop a product, be it the selection of the materials or their combinations, or if for production technical reasons components must be optimised. We show you alternatives in the scope of moulded conception, develop prototypes and more.

In doing so, quality assurance is of decisive importance: Standards help us to reach the desired level or to keep it. We thus carry out the first sample according to the VDA or PPAP process.

Use our expert knowledge, we look forward to your demands!

Development

Do you have an idea or a problem? We can help you in finding a solution with our highly qualified employees. We draw up the specifications and take on the tasks: our speciality is the individual and tailor-made solution.

For this we fall back on external development capacities which we have access to. Everything so that you can find an optimal support: from the concept to the consultation down to the finished product. Design-to-cost is not a foreign word for us, we have the know how in the production technology.

In order to determine the component geometry we use the most modern IT processes:

- FEA calculations

- Calculations of load force and vibrations (animation)

- Calculation of stress (of Mises)

For example our solutions for acoustic and vibration technical challenges in the automobile branch lead to the highest customer satisfaction already today: and thus we have reached an essential goal in our company policy.

We look forward to you being a part…

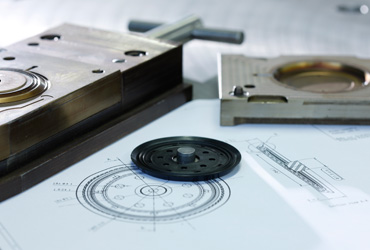

Moulds

We see our task in the complete realization of your wishes and specifications. As the producer of moulded parts, we pay attention to special care: we produce rubber moulded parts and rubber bonded parts according to your individual ideas and will live up to your quality demands. It is a matter of course for us that we apply the same standards in mould construction.

You will recognise our professionalism in the qualified consultation. We face your demands: this is not a problem because we have the experts you need.

Of course we are no theorists: The new construction of moulds is part of our portfolio and our task is completed when your ideas and wishes are realised. Test us!

Prototypes

Before the mould goes into serial production, it is recommended to make a prototype mould. Again it’s about optimisation, precision and care: it’s about the quality of your products.

The closeness to the series is crucial: Original materials are used for the production of the test parts. In doing so, the mould concept is optimally constructed and refined. Of course the time and cost factors are to be taken into consideration. This means: Optimizations of the component geometry as well as test series with differing elastomers are carried out at short notice and at low costs.

Sample parts or sample moulded parts are assessed in a first sample testing report, rubber mixtures are specified in a mixture data sheet.

You see: we take our service demands and your specifications seriously!

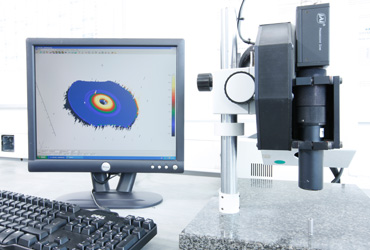

Quality

Your QM commissioners determine the suitable testing procedure, documentation and testing frequency together with our specialists. In doing so, the experience of our employees is your essential advantage. Also available to you are highly modern testing facilities.

Serial tests are individually adapted to the components. There are for example impermeability tests for membranes both through optic test facilities as well as through pressure loss measure-ments. Testing machines which allow ppm numbers of 40 test for example double lip seal rings through optically 100% controls.

For the first sampling, a contactless, optic measurement machine from TESA (Switzerland) is used. We use high-quality rubber mixtures in order to satisfy your specifications. You are given optimal safety of the delivered products through our 100% final control:

Each piece will be inspected before delivery!

It is a matter of course for us that we produce according to DIN EN ISO 3302-1, which is used in the rubber industry, and for you it is the guarantee for performance level and quality!

Production

Our company goal is your satisfaction. We achieve this with our reliability which we ensure with our highly modern machines, with our competent employees, with our tested production process.

The good preparation with a competent partner is the best prerequisite for the optimal result: the entire planning of the production technical solutions in the development talks offer the best basis. Thus from the beginning of the cooperation we keep in mind that we will best serve your production process. We guarantee process security, because this is the guarantee for a serial delivery which is free from disturbances.

Together with you we set the mould conception for the suitable injection mould machine, develop working and testing plans which ensure a standard quality for our products. Our machines range from 80 ton injection machines for the smallest moulded parts up to 400 ton injection machines for our XXL products.

The suitable and high-quality rubber mixture is the basis. For this we fall back on our experienced and professional partners: Quality is the top priority.

In our vulcanising department only Compounds (rubber mixtures) from renowned, certified mixture suppliers are used. In connection with the correctly prepared metal and plastic parts, the result is a high-tech performance – bonded parts which satisfy the highest demands.

The correct preparation of the carrier materials decides the quality of the compound part. Therefore in our department “metal and plastic preparation” only the newest and most reliable equipment technology is used.

Our water based adhesion systems allow for our striving for an environmentally sound production.

Depending on the application, our production processes reach from Injection moulding with cold runner technology through the traditional Pressing process . From large to small series, we cover your entire needs for elastomer parts.

Experienced, continuously trained and highly motivated personnel guarantee a reliable processing of orders under the premises of the “zero error deliveries” and “on time deliveries”.

Materials

All used elastomers correspond with the current EU guidelines, in particular with the

- EU directive 2000/53/EC old car ordinance

- EU directive 2002/95/EC RoHS

- EU directive 2002/96/EC WEEE

- EU directive 2003/11/EC fire protection means.

Approvals of the automobile and foodstuff industry, KTW D1/D2, W270, UL94, colours and shore hardness upon request. With special applications rubber mixtures can be newly developed according to your needs and tested.

Galvanic coverings with used steel parts are free of Chrome VI.

| International abbreviations with link to the rubber dictionary |

NR | SBR | EPDM | IIR | CR | CO/ ECO |

NBR | HNBR | CSM | EU/ AU |

ACM/ EAM |

FPM | VMQ | FVMQ | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Hardness range Shore A |

30-90 | 35-90 | 30-90 | 30-80 | 25-90 | 40-90 | 30-95 | 45-98 | 45-90 | 55-90 | 40-90 | 40-90 | 30-85 | 30-80 | |

| Thermal behaviour |

Cold flexible to °C |

-55 | -30 | -50 | -60 | -35 | -35 | -30 | -45 | -30 | -30 | -30 | -20 | -65 | -45 |

| Max. ongoing use Temp. in °C |

80 | 100 | 130 | 130 | 100 | 130 | 110 | 150 | 130 | 120 | 150 | 200 | 200 | 200 | |

| Stability against |

Petrol |

– – – | – – | – – – | – – | + | ++ | ++ | + | + | ++ | – – | +++ | – – | +++ |

| Mineral oil at 100°C |

– – – | – – | – – | – – – | + | +++ | +++ | ++ | + | ++ | +++ | +++ | ++ | +++ | |

| Acids (25% sulphuric acid at 50°C) |

– | – | +++ | +++ | ++ | +++ | ++ | +++ | +++ | ++ | + | +++ | – | + | |

| Bases (50% sodium hydroxide at 50°C) |

++ | ++ | +++ | +++ | ++ | ++ | – – – | + | +++ | – – – | – – | +++ | – – | + | |

| Water (at 100°C) |

– – | – – | +++ | ++ | + | ++ | ++ | +++ | + | – – – | + | ++ | ++ | ++ | |

| Weather and ozone |

– | – | +++ | + | ++ | +++ | – – | +++ | +++ | ++ | ++ | +++ | +++ | +++ | |

| Light |

– | – | ++ | + | + | – | – | +++ | +++ | ++ | + | +++ | +++ | +++ | |

| Gas impermeability |

– – | – | – | +++ | + | ++ | ++ | ++ | + | ++ | + | +++ | – – – | + | |

| +++ | excellent | – | satisfactory |

| ++ | very good | – – | bad |

| + | good | – – – | insufficient |